Addressing Power Consumption with ADI MAX78000

The combination of artificial intelligence (AI), the Internet of Things (IoT), and industrial automation achieves more than previous generations could have dreamed of. Still, amid all the advancements and success, at least one challenge persists: microcontrollers for AI applications require significant power, leading to additional complications. Generally, the more influential the AI, the more power it requires.

Figure 1. Artificial Intelligence combined with the Internet of Things and industrial automation achieves beneficial results, but often at the cost of excessive power consumption. Image provided courtesy of Pixabay.

However, engineers do not have to settle for high-power AI chips. This article reviews the issues with AI and power and then discusses how the ADI MAX78000 addresses these power problems with ultra-low power consumption. It also includes a reference design to show how engineers can use the hardware.

AI and Power Consumption

An article in Scientific American points out the tremendous amount of electricity used by AI, much of it for the training and inference phases and for cooling the systems involved in the process. This energy consumption will become a greater problem as AI technology implementation grows. This issue does not only affect large-scale AI servers, but it also poses problems for smaller-scale AI implementations.

Rechargeable and battery-powered solutions, including IoT, consume as little power as possible but highly depend on AI microcontrollers for functionality and performance. The power required for AI will shorten the time these devices have to perform their assigned tasks, forcing them to stay close to their rechargeable power source.

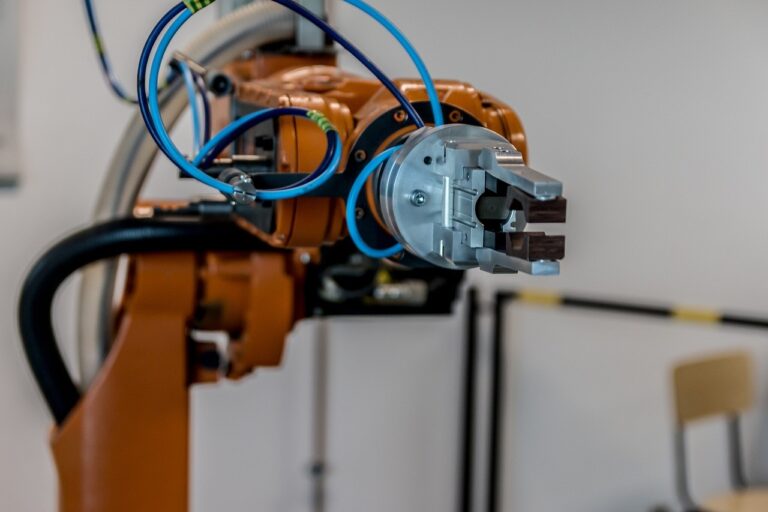

Another example is industrial automation. Battery-powered devices, whether small robots carrying parts from one place to another or key sensors for predictive maintenance, have limited run time and may require additional components to keep their circuits from overheating.

Figure 2. Industrial automation in manufacturing facilities requires significant power just for the AI required. Image provided courtesy of Pixabay.

Furthermore, high power consumption generates heat that can complicate designs. Heat dissipation measures are included, making the final product more expensive, heavier, and larger. If not addressed, generated heat can lead to unexpected behavior and failure.

The ADI MAX78000

The ADI MAX78000 is a hardware-based deep convolutional neural network (CNN) accelerator that enables neural networks to work at ultra-low power. It enables battery-powered applications to execute AI inferences using only microjoules of energy via their power management capabilities and dynamic voltage scaling that minimizes active core power consumption.

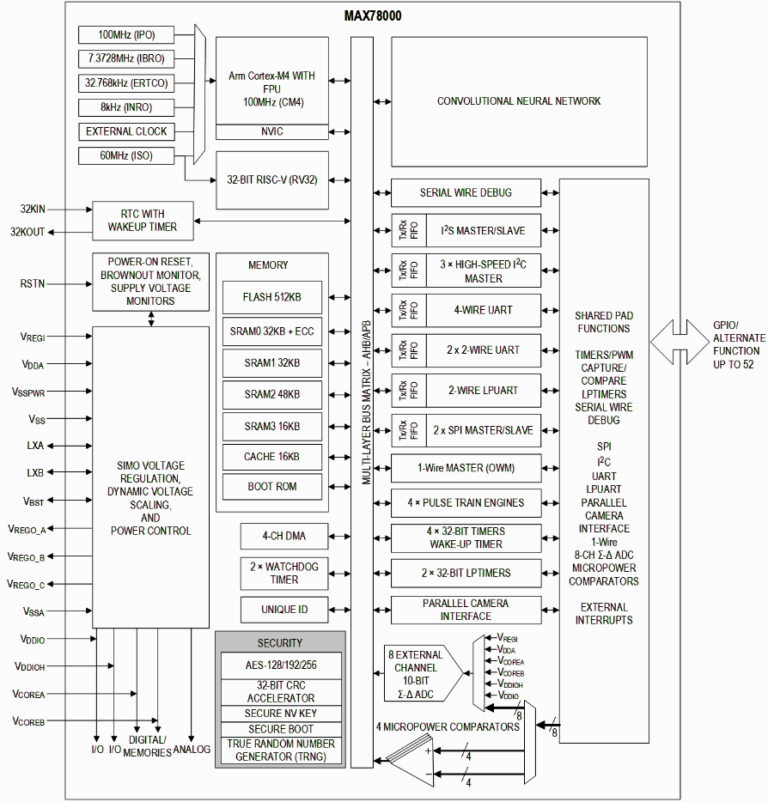

Figure 3. Simplified block diagram for the ADI MAX78000. Source.

The MAX78000 is an advanced system-on-chip featuring an ARM® Cortex®-M4 with an FPU (floating-point unit) CPU for efficient system control. It includes FPU up to 100MHz, 512KB flash, and 128KB SRAM. The CNN engine has an SRAM-based weight storage memory of 442KB, can support networks of up to 3.5 million weights, and process AI network updates on the fly. In addition, the CNN engine has 512KB of data memory.

The CNN architecture has been engineered for flexibility. It supports networks trained in conventional toolsets (e.g., PyTorch and TensorFlow) and then converted for execution on the MAX78000 using tools provided by Maxim.

Applications for the MAX78000 include object detection and classification, facial recognition, multi-keyword recognition, noise cancellation, sound classification, multi-sensor analysis, and predictive maintenance. The MAX 78000 is ideal for industrial automation and IoT applications, including those that rely on battery power.

Reference Design

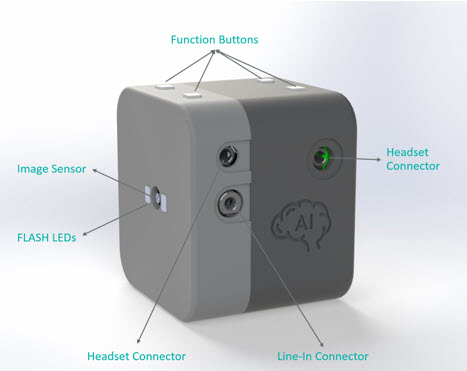

IoT and industrial automation often use cameras to capture digital images for processing by AI modules. The MAXREFDES178 (Figure 4) is a cube camera containing two MAX78000 ARM Cortex M4F Microcontrollers with a CNN accelerator unit designed for edge AI applications such as facial and object identification and keyword spotting. It works for security, assembly line automation, quality checks, and more.

Figure 3. A digital cube camera using MAX78000 hardware can be used in a variety of AI applications, including security and quality check. Source

Its hardware comprises a connectivity board based on the MAX32666 and an AI board using two MAX78000 chips. A short 33-position flex cable connects the boards, and the system is battery-powered.

Learning More About ADI MAX78000

Integrating AI, IoT, and industrial automation presents revolutionary advancements — but with a notable challenge: high power consumption. ADI has introduced its MAX78000, a hardware-based deep convolutional neural network (CNN) accelerator designed for ultra-low power consumption to address this issue.

The MAX78000 provides dynamic voltage scaling and power management capabilities to enable AI inference with ultra-low energy consumption, making it suitable for battery-powered applications in a range of applications. To learn more about the MAX78000, contact Excelpoint today.

© 2025 Excelpoint Technology Pte. Ltd. All Rights Reserved.